Shanghai Electric is a decisive equipment manufacturing group ranked first in China's machinery industry sales.In 2019, Shanghai electric placed 49th with 81.276 billion yuan on the list.

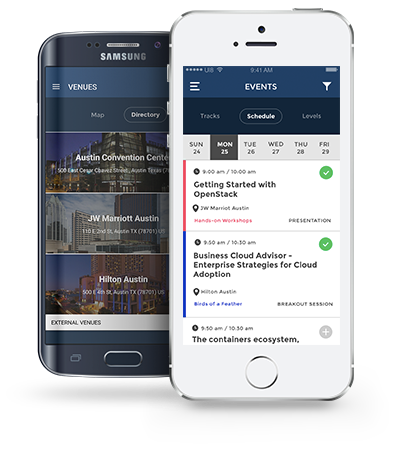

Shanghai electric is the forerunner of industrial technology innovation.The company builds an integrated digital factory with OpenStack, managing the linkage between edge computing and cloud data center, so as to activate production line, improve operation efficiency and save cost.In the chain of digital industry, OpenStack runs through the whole process of data collection, data aggregation, data analysis and data display, which connects the last mile of experience-driven to data-driven, providing safe and stable infrastructure architecture for the group headquarters and 67 enterprise units.

So,Shanghai electric sets up an innovative platform based on OpenStack, which has a current scale of 100 nodes and a planned 1,000 nodes.

1、 How does Shanghai Electric set up an OpenStack-based Edge Cloud platform?

2、 How can Shanghai Electric manage data collection, aggregation and display of edge terminal system through OpenStack technology ecology?

3、 Faced with diversified industrial protocols, how can Shanghai Electric achieve low latency and high efficiency of data transmission?

4、 In the face of massive marginal production data, how does Shanghai Electric meet the safety industry 4.0 standard?

5、 How does Shanghai Electric integrate OpenStack with the third party operation and maintenance platform to build the Edge Cloud platform with high level of intelligence and automation?

6、 How can Shanghai Electric solve the problem of fast acquisition frequency and inconsistent data format of edge terminals in OpenStack environment?